The Petillo Acoustic Tonal Sensor™

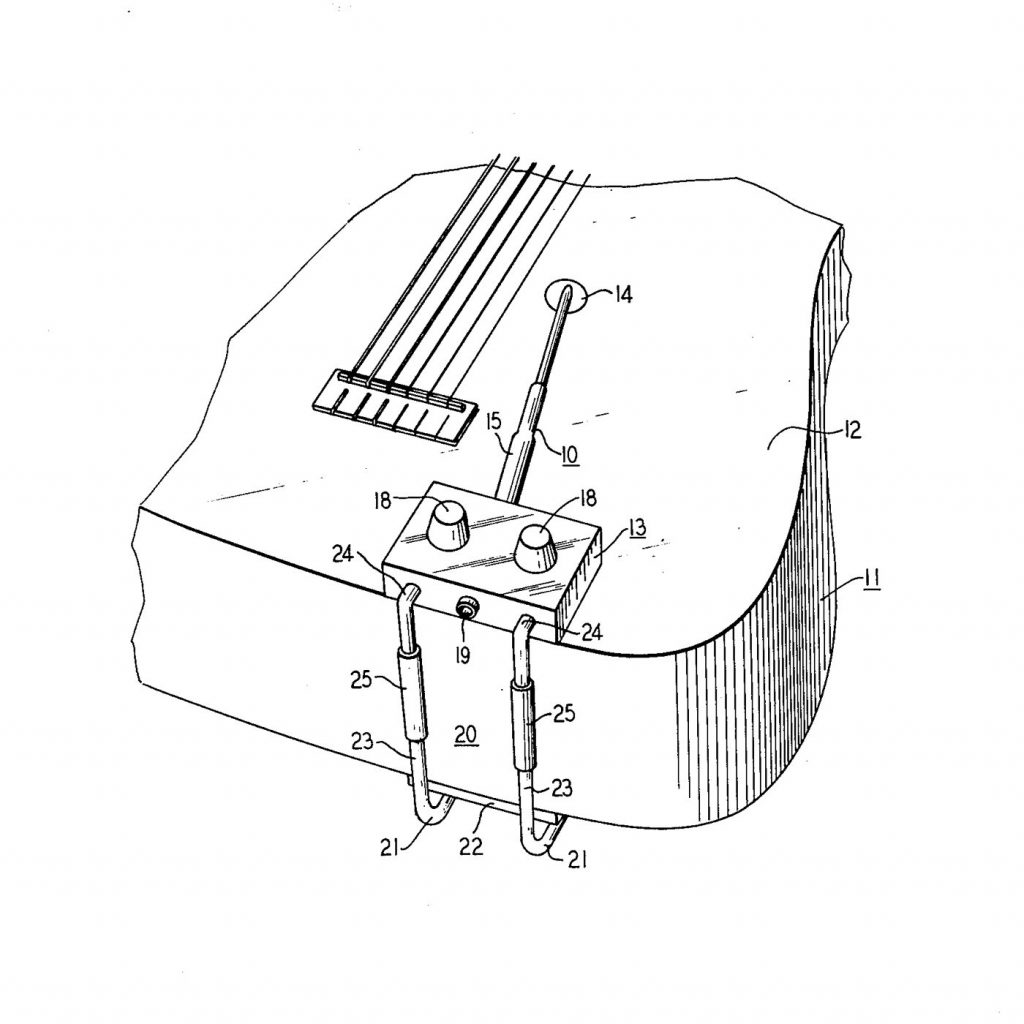

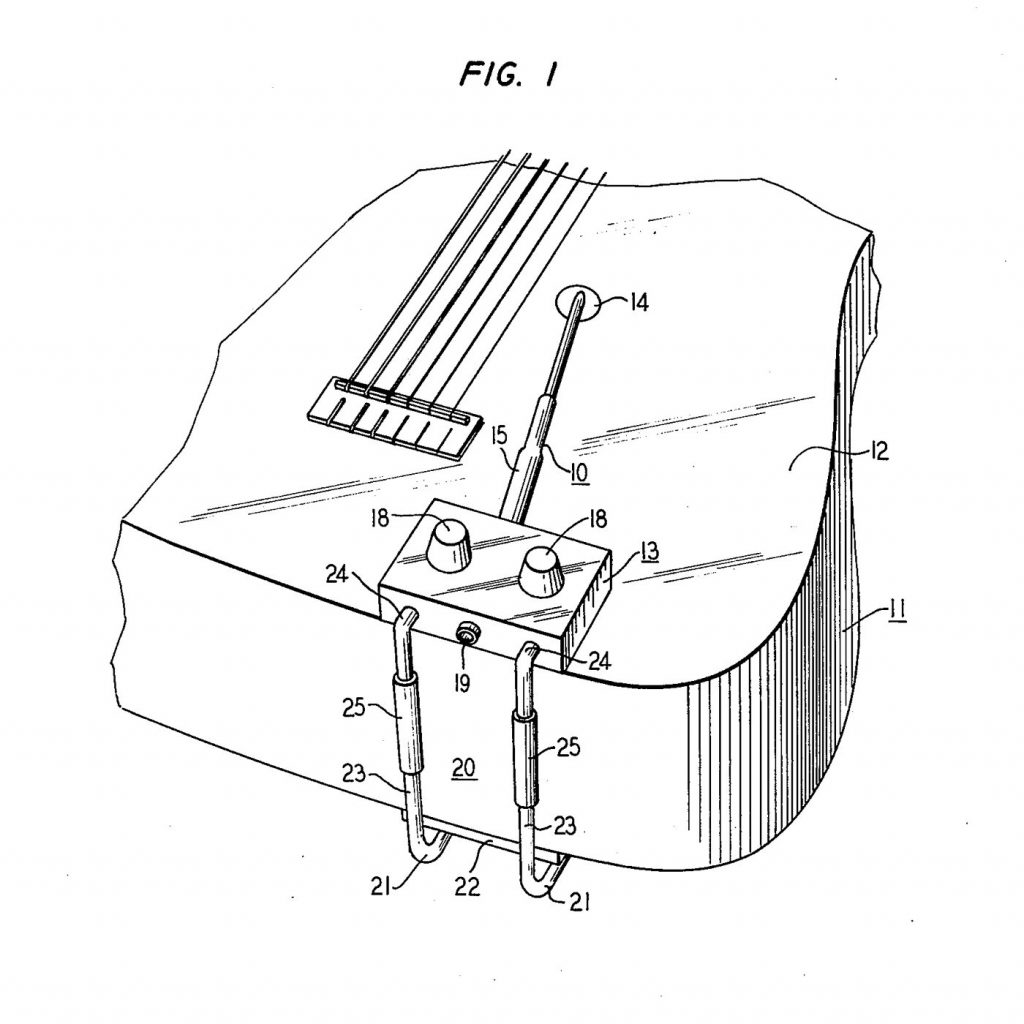

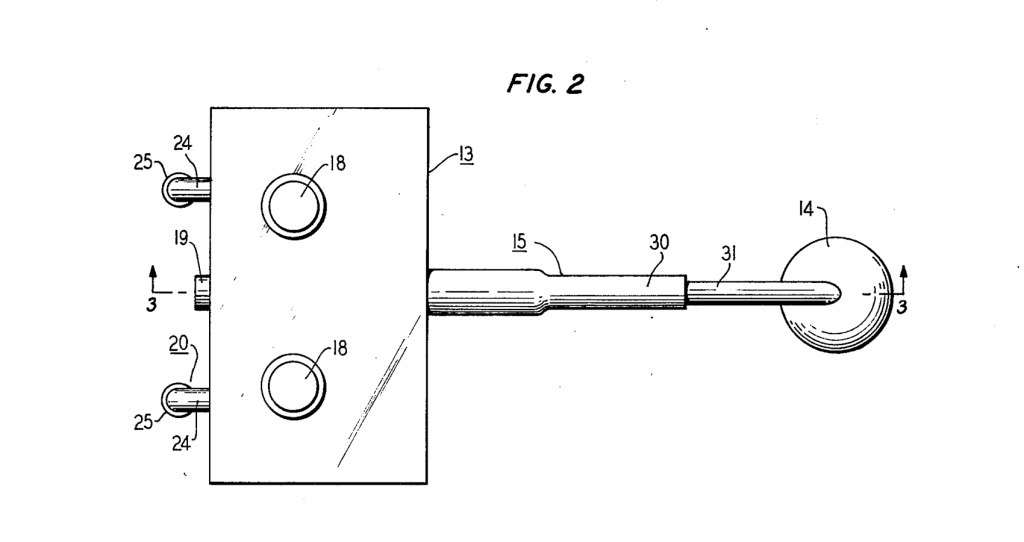

U.S. Patent No. 4,168,647

Why Is It Better?

Acoustic pickups or transducers for the most part are contact microphones. They are attached to the instrument by some means. Most of the time the pickup is attached to the top of the instrument. The basic definition of a microphone is a device for converting sound, mechanical waves, or motions into electrical signals.

There are many types of pickups, transducers, or microphones. Most of them are comprised of carbons, cardioids, condensers, crystals, or magnetic types, etc. What is attempted by all acoustic pickups is to reproduce the acoustic sound of the instrument perfectly? Unfortunately, most acoustic pickups do not reproduce what the instrument sounds like. Most of the time they sound very metallic, hollow, or unbalanced with a lot of feedback. This is why most pickups need preamps and other devices to even be useful and sometimes that doesn’t work.

Through many years of experimenting with hundreds of types of pickups and other microphone like elements, we have chosen to use a modified type of piezoelectric device. This type of piezoelectric is most active and sensitive that we found. It works by producing electrical voltages when subject to mechanical stress; such as attaching the device to the inside soundboard of the instrument. When the strings are played, vibrations are put forth by the soundboard, these vibrations cause the wood fibers to flex, twist, or to be under stress. These actions are converted into electrical signals, which the amplifier then multiplies the signals into audible tones.

The piezoelectric device, which we have given the name of “Toner Sensor”, is made up of a new type of material called “Barium Titanate” (B. T.). This material is compressed and heated to form one of these sensors. After this is accomplished, the sensor is electroplated with different types of plating. A brass, alloyed disc is then cut out and the B.T. is attached to the disc. Brass was chosen in this application because of its unusual harmonic ability.

The attachment of B.T. to the brass disc is important to insure strength because of its brittle nature, and must be protected. When this long process is completed into a toner sensor, the passive electronic components, shielded cable, and an output jack are attached. At this point the sensor is ready for installation.

This pickup assembly needs no batteries, preamp, or unnecessary holes. The sensor is designed to accept only selected frequencies, reject unwanted frequencies and will match any system. The toner sensor provides a perfect natural sound, very low feedback; clean with excellent presence, harmonic, symmetry, and true pure tone.

Dr. Petillo’s Detailed Perspective: The Acoustic Tonal Sensor™

The Acoustic Tonal Sensor™ is a device to reproduce exact acoustic tones. The term sensor is a device that responds to physical stimulus (as heat, light, sound, pressure, magnetism, or a particular motion). By studying different types of wood technology, we’ve discovered a method to take advantage of wood. How? Wood, in general has several things, which are very interesting to observe such as, wood fibers and pores. Wood fibers have elongated cell structures with pointed ends contributing notably to the strength of the wood. The pores of the wood are the cross section of the wood fibers. Fibers and pores have elements present such as, parenchyma (thin walled wood cells); these areas in the wood vibrate when excited such as when strings vibrate, these cells move in many directions.

Because of this, we see an advantage, which is energy. The device I invented senses these cell movements and turns them into voltage, this process is called piezoelectric. The materials used to make a piezoelectric device are Ethylenediamine Tratrate Crystals and in combination with Barium Titanate modified with high temperature stabilizers that are pressed into various shapes, these shapes allow for frequencies to be made from the vibrations of the strings moving the wood fibers and pores. When the vibrations reach the sensor, the vibrations cause the sensor element to flex.

This flexing makes a voltage and that is seen by the amplifier as a signal and then an audio sound. We modified this formula to be selective in what frequencies it will accept and reject. Some frequencies need to be rejected because they cause the output sound and tone to be phased distortions with a hollow metal sound. In contrast to vibrational curves an harmonic resonant harmony. We hope this helps you understand what our research has discovered.

For more information on this subject consult the following books:

1) On The Sensations Of Tone (By: Hermann Helmholtz)

2) Merck Index Twelfth Edition

3) Investigations On The Theory Of The Brownian Movement (By: Albert Einstein)

4) Van Nostrands Scientific Encyclopedia 5Th Edition (Edited by: Douglas M. Considine)

5) Music, Physics, And Engineering (By: Harry F. Olson)

6) The Encyclopedia Of Chemistry (By: Clifford A. Hampel)

7) Materials Handbook 11th Edition (By: George S. Bradey, Henry R. Clauser)